The conditions in dispute are Nos 5, 13 and 17 which state that:

"Overal Conclusion:

121. I conclude that conditions 5, 13 and 17 meet the local and national policies for protection of residents from the effects of dust, noise and visual impacts. It has not been demonstrated that the economic viability would be affected to an unreasonable degree by imposition of these conditions. I am also content that the conditions meet the policy tests in paragraph 56 of the NPPF, being necessary, relevant to planning and to the development, enforceable, precise and reasonable in all other respects.

122. The appeal is accordingly dismissed." B. Davies - INSPECTOR

An application for costs was made by Hills Quarry Products Limited against Wiltshire Council. This application is the subject of a separate Decision.

Conclusion

9. In light of the above, I find that the reasons for refusal were supported by detailed evidence and that unreasonable behaviour resulting in unnecessary or wasted expense, as described in Planning Practice Guidance, has not been demonstrated. An award for costs is therefore not justified."

B Davies - INSPECTOR

Hills Quarry Products Limited’s initial planning application in 2016 was to extract a small amount (around 300,000 te) of very fine sand over a 6 year period from an area of around 11 hectares situated in the heart of Compton Bassett Parish, close to 4 dwellings at Freeth Farm and around 1km from the majority of houses in the settlement of Compton Bassett and is linked to Hills other planning application for an open conveyor system to move the sand.

Unfortunately, Hills’ Freeth Farm application is classified as a dormant ROMP which meant that they already have planning permission and are only subject to up to date planning conditions.

So the argument was not whether Hills could be stopped (as it couldn’t) but whether Wiltshire Council could be persuaded to update the planning conditions to give Compton Bassett residents proper environmental protection.

Hills initial applications in 2016 proposed a buffer zone of 10m from Freeth Farm Cottages using a wall of straw bales to mitigate the noise. This was refused because of the sand instability around Freeth Farm Cottages would cause subsidence and the straw bales were a health and fire hazard.

So the argument was not whether Hills could be stopped (as it couldn’t) but whether Wiltshire Council could be persuaded to update the planning conditions to give Compton Bassett residents proper environmental protection.

Hills initial applications in 2016 proposed a buffer zone of 10m from Freeth Farm Cottages using a wall of straw bales to mitigate the noise. This was refused because of the sand instability around Freeth Farm Cottages would cause subsidence and the straw bales were a health and fire hazard.

At that time Hills didn’t even own the land at Freeth Farm, they only bought it in 2018, so the application was purely speculative. Hills must have known that a similar application by Aggregate Industries was turned down in 2007.

But Hills are nothing if not persistent and they resubmitted the application with a 35m buffer zone; 4m high by 19m wide giant noise attenuation bunds next to Freeth Farm Cottages; and with open conveyors to transport the sand. They claimed that this would provide adequate environmental protection for Compton Bassett Residents.

However, a 35m buffer zone is not in line with the normal UK planning authority practice (100m); does not meet the DoE planning guide (100m); and does not meet the Institute of Air Quality Management guidance (100m). The giant noise attenuation bunds cannot achieve statutory noise limits and the 35m buffer zone and the open conveyor transport would pose a carcinogenic silica dust health hazard.

However, the “35m application” was recommended for acceptance by Wiltshire Council on the basis that their Environmental Health Officer had no objections or concerns whatsoever as he believed that the Freeth Farm sand was coarse and would always be damp.

Wiltshire Council wanted a bigger buffer zone but were pressured by Hills to accept 35m and to waive normal environmental protections because Hills claimed that the application was only marginally economic so that any increase in the buffer zone would be uneconomic which would deprive Wiltshire of much needed building materials.

Hills financial claims were initially kept secret on the basis that they were commercially confidential but after some pressure was applied the details were eventually released for proper public scrutiny.

An Independent Review was prepared by Peter Alberry which showed that Hills had grossly underestimated the project IRR by using:

Each of these items was independently verified by using unbiased sand density data from the literature; sand extraction and processing losses taken from DEFRA and item 3 was even confirmed by Wiltshire Council’s own independent assessment.

If these factors are included, Hills’ IRR dramatically increases from 9.3% to 30%.

This meant that the buffer zone could be increased to 100m from the occupied Freeth Farm Cottages in line with common practice (but not best practice) and Hills’ profits would still be 18-21% which what most house builders achieve.

But the real problem is that the Freeth Farm silica sand is ultra-fine and classified as a Grade 1 carcinogen. The health risk arises because the ultra-fine silica particles (known as PM10’s in the trade) get into the deepest parts of the lungs when inhaled air and then pass into the bloodstream. The Health and Safety Executive advise that chronic or long-term exposure to about a quarter of a million PM10 particles in 24 hours can lead to lung inflammation and produce a severe lung disease known as silicosis.

You can try Googling Respirable Crystalline Silica: The Facts.

Breathing in this amount of silica dust in 24 hours is enough to give you lung cancer

Picture taken from UK health & Safety Executive Publication

Picture taken from UK health & Safety Executive Publication

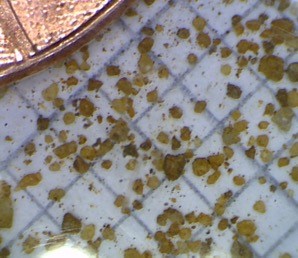

Freeth Farm Sand Particles under a Microscope

The fine black dots are carcinogenic PM10 particles

The fine black dots are carcinogenic PM10 particles

Hills convinced Wiltshire Council’s Environmental Health Officers that, as the sand was coarse and would always be damp, there was no health risk whatsoever.

But Hills shot themselves in the foot. In trying to prove that the sand was coarse, their own evidence showed that the sand was a “0/2mm FP Cat f3 fine concreting sand” classification. They appeared to have used this complex classification without explanation to bamboozle Wiltshire Council into agreeing that the sand was coarse, which they did.

On closer investigation, it turns out that this is the finest of fine sand classifications and means that up to 3% of the sand by weight (or 30 grams in every kilogram) will pass through an ultra-fine 63m sieve. Since one 63m sand particle weighs about half a millionth of gram, this means that every kilogram of Freeth Farm sand would contain around 70 million ultra-fine silica particles.

Charles Reis then had the actual particle sizes measured by specialised consultants and they found 100 million PM10 particles per kilogram.

Obviously this is unusually fine sand and it could be a significant carcinogenic health risk if any of it dried out during the extraction of 307 million kilograms of sand at a rate of 36,000 kilograms per hour for 4-5 years before being transported to Lower Compton on open conveyors.

Hill’s giant noise attenuation bunds that form the 35m buffer zone are so massive (up to the height of first floor windows) that they need 50 million kilograms of sandy topsoil, so they are also a health hazard.

The Department of the Environment Planning Guide, Section 5.3 states that:“Residents living in proximity to quarries can potentially be affected by dust up to 0.5km from the source, although continual or severe concerns about dust are most likely to be experienced within about 100m of the dust source. Respirable particles, i.e. those less than 10 micrometres (10μm) in diameter, have the potential to cause effects on human health, depending on exposure levels”.

The Institute of Air Quality Management (IAQM) Guidance on Mineral Dust states that: “Large dust particles (greater than 30 μm), which make up the greatest proportion of dust emitted from mineral workings, will largely deposit within 100m of sources. Intermediate-sized particles (10–30 μm) are likely to travel up to 200–500m. Smaller particles (less than 10μm) which make up a small proportion of the dust emitted from most mineral workings, are only deposited slowly but may travel 1000m or more”

Hills argued that the dust risk would be assessed visually by their on-site manager and controlled by the use of water bowsers to keep the sand wet. To be fair if the sand always stayed damp then there would be a minimal health risk.

However, the ultra-fine dust particles can dry out very quickly and are not actually visible so the water bowser method of control is not at all adequate even assuming that the operators are vigilant. A continuous dust monitoring system is clearly required to protect local residents.

Continuous dust monitoring systems are inexpensive, simple to implement and easy to operate. They are used routinely to monitor small particle PM10 emissions due to road traffic, particularly large diesel HGVs. But it’s easy to understand why a quarry operator might prefer not to have such controls.

Hills tried to claim that there is always a dust risk in the area during farming activities such as ploughing. However, ploughing only usually occurs around twice a year. That is in the Winter months before planting, usually 1-2 days and again in late Autumn after harvesting. On these occasions, the ground is wet and there is minimal dust release as the ploughs don’t penetrate into the fine sand.

There is also a noise problem. Even the giant noise attenuation bunds cannot achieve statutory noise limits during normal working and noise levels would reach 70dB for 8 weeks every year for top soil removal and bund construction.

Hills proposed to monitor the noise 4 times per year as they argued that continuous noise readings could be distorted by external noise factors such as farm machinery and aeroplanes. This was also recommended as acceptable by Wiltshire Council’s Environmental Health Officer.

Hills application was considered by Wiltshire’s Strategic Planning Committee on Wednesday 14 July 2021 and a number of representations statements were made to the committee by Peter Alberry, John Brooks (on behalf of James Pendley), Charles Reis and Councillor Nick Botterill (on behalf of Ashley O’Neill our Wiltshire Councillor).

The strategic planning committee were persuaded that the giant bunds could be avoided and proper environmental protection should be provided for Compton Bassett residents and the planning conditions now include:

Note: A 70m buffer zone from all property boundaries is 100m from the properties themselves.

Hills have now gone away to re-work their plans to accommodate the new planning conditions.

So as the sand is now likely to remain damp and there will be continuous dust monitoring, the health risk has been reduced to normal levels and the excavation time has probably been reduced by up to a year.

This is probably as good as could have been achieved given that the ROMP proposal could not be refused, and in any event, even if had been refused Hills could always appeal to a favourable planning inspector as they have done in the past. In the present economic climate they might easily have won.

Unfortunately, Hills can also still appeal the ROMP permission planning conditions by claiming that they are too strict and try to get them reduced. But as the project is still economic; open conveyors are now industry best practice; and the 70m buffer zone is already technically slightly lower than the normal practice of 100m, they are not likely to win.

There is always the possibility that they won’t proceed ….

Dr Peter Alberry